Installation

EM500 Transceiver Installation

The transceiver supports wall, pole or DIN rail mounting.

Note: Keep the transceiver away from metal objects and obstacles for

better signal.

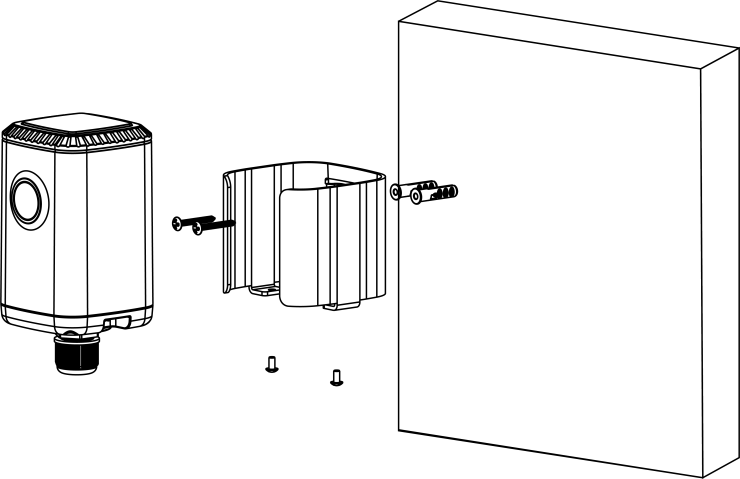

- Wall Mounting

-

- Drill two holes in the wall according to the mounting bracket, then secure the wall plugs into the wall.

- Fix the mounting bracket to the wall via screws.

- Place the device onto the mounting bracket, then secure it to the bracket with two fixing screws.

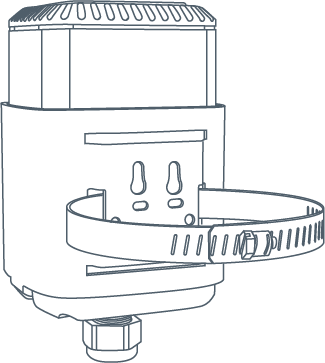

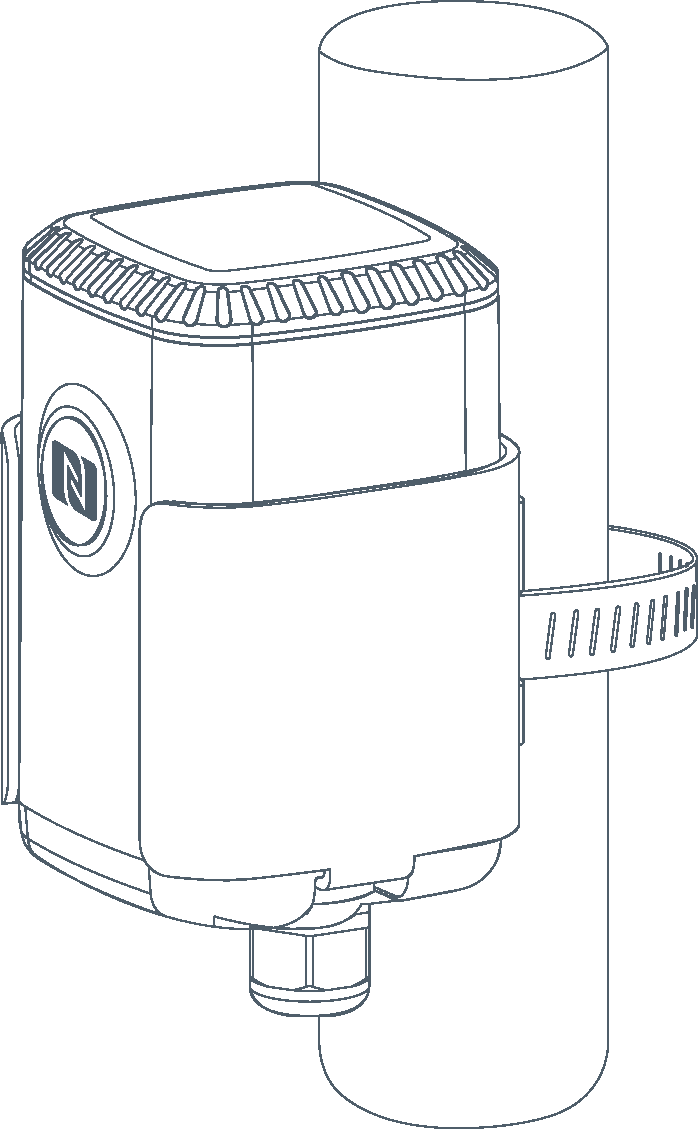

- Pole Mounting

-

Straighten out the hose clamp and slide it through the rectangular holes in the mounting bracket, and wrap the hose clamp around the pole. After that, use a screwdriver to tighten the locking mechanism by turning it clockwise.

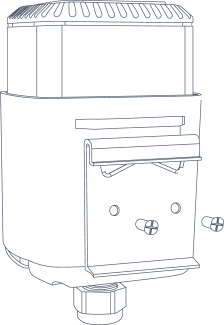

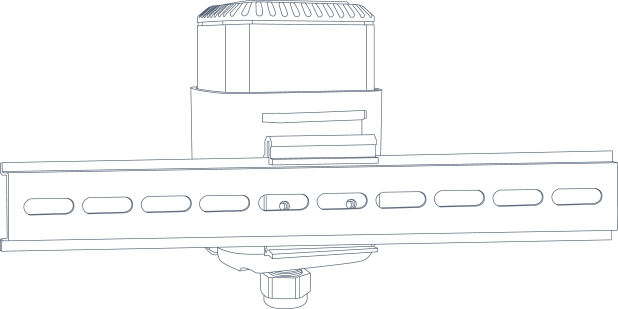

- DIN Rail Mounting

-

Use 2 pcs of M3 × 6 flat head Phillips screws to fix the mount clip to the bracket, and then hang the device on the DIN rail. The width of the DIN rail is 3.5 cm.

Pipe Sensor Installation

- The selected installation position should reflect the actual situation of the measured pressure. Install the sensor in the pipe where the measuring medium flows straight and avoid the location of bends, splits, dead corners, or other places where vortices are easy to form.

- Pay attention to whether the pressure sensor is too close to the valve or pump when installing. Because the opening and closing of the valve and the start and stop of the pump will impact the diaphragm of the pressure sensor, causing diaphragm damage.

- Install the sensor in a low-vibration environment.

- Install a damper in order to prevent the pressure spikes or surges if you use EM500-PP with high-pressure hydraulic or other liquid equipment.

- When freezing occurs in winter, the pressure sensor installed outside must adopt anti-freezing measures to prevent the liquid in the pressure inlet from expanding due to icing, which may cause damage to the pressure sensor.

- When measuring steam or other high-temperature gases, add a condenser such as a buffer tube (coil), and the operating temperature of the pressure sensor should not exceed the limit.

- Do not insert a foreign object into the pressure diaphragm in an effort to simulate pressure, which may cause permanent damage.

- Clean the sensor termly in cases of high corrosion or high dust.