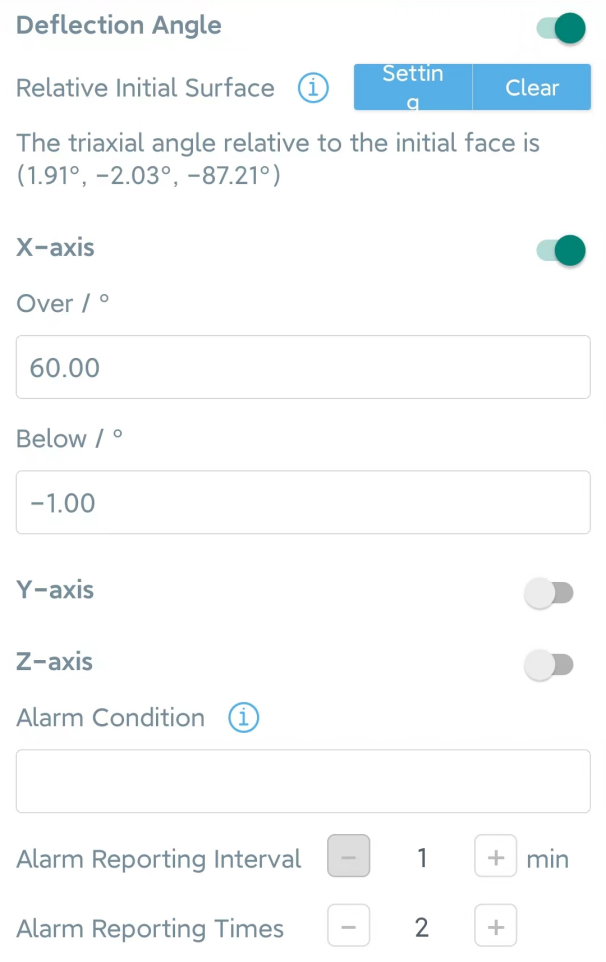

Threshold Setting

You can set a relative initial surface to measure the deviance from an initial one, when the device detects the angle of a certain axis reaches the threshold based on the initial position, it will upload the current data instantly.

| Parameter | Description |

|---|---|

|

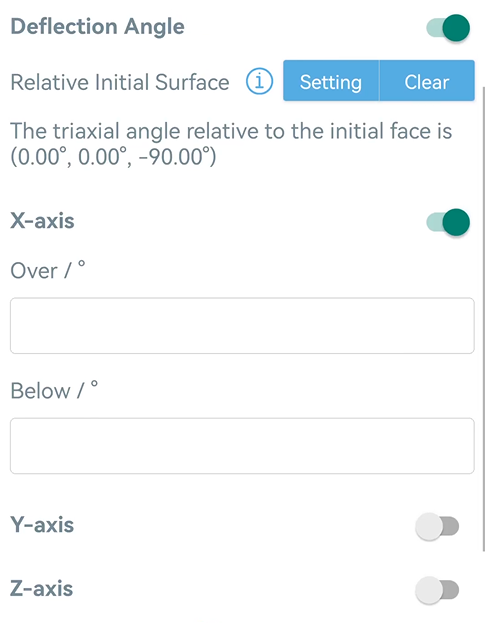

Relative Initial Surface |

Click Setting to set current position of device as initial position to measure the deflection angle. Click Clear to change the initial position back to (0.00°, 0.00°, -90.00°). Note: after writing Setting or

Clear configuration, click Read to read the

device to check if the initial position changes

successfully.

|

|

Over / ° |

The maximum/upper limit of angle threshold. |

|

Below / ° |

The minimum/lower limit of angle threshold. |

|

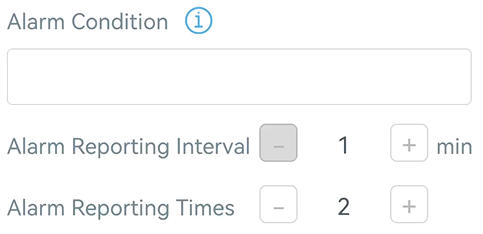

Alarm Condition |

Acceptable elements are “X”, “Y”, “Z”, “and”, “or” “only”, it takes 2 or 3 axes to complete an expression and the device will only read from left to right. If left blank, it will consider the condition as “or”. Example:

|

|

Alarm Reporting Interval |

After the threshold is triggered, the device will detect if the threshold is triggered again according to this reporting interval. |

|

Alarm Reporting Times |

After the threshold is triggered, the device will detect according to Alarm Reporting Interval and if still triggered, the device will send the certain number of alarms to NS. |

Example:

When X axis is detected to 0° (0° - 1.91° = -1.91° < -1°), it will trigger the threshold and upload a alarm package right away. If it changes back to normal, the device will also upload a data package immediately; if not, it will send alarm package after 1 minute. This process will repeat 2 times.